Jamie Gregg is admittedly difficult to get ahold of these days — and it’s not just because he’s the CEO of Colonial Bronze, an esteemed architectural hardware manufacturer that’s been in the business for 93 years. Founded in 1927, the Connecticut-based company landed in Gregg’s hands when his father decided he was ready to retire and put Colonial Bronze on the block. “I swore I’d never do it,” Gregg told us of his decision to quit a high-powered job in New York to helm the family business. “I was an assistant U.S. attorney in Manhattan and I was working seven days a week — long, long days. It was a lot of stress … I wanted something a little more realistic that would give me a life. So I came up to Connecticut.”

After taking over The Bronze, as the company is familiarly known, Gregg put his years of experience as a medical malpractice litigator to use on the board of directors of a local hospital. Working with the hospital board’s Quality Committee, Gregg began to focus his attention on the troubling realities of hospital-acquired infections. “It’s been a significant problem,” he admitted. “[And] I was looking around for something and thinking, ‘What can we come up with that will deal with these problems that the hospitals confront?’” Gregg was also following the Copper Development Association’s research on the antimicrobial effects of copper. Inspired by the encouraging findings of a study that equipped hospital rooms with copper-alloy fixtures, Gregg developed a strategy for The Bronze to help combat hospital-acquired infections. With a name that fuses copper’s symbol on the periodic table and the Latin word for health, his brainchild CuSalus is now an EPA-registered, Nightingale Award-winning, antimicrobial copper alloy that can be found in hospitals across the country.

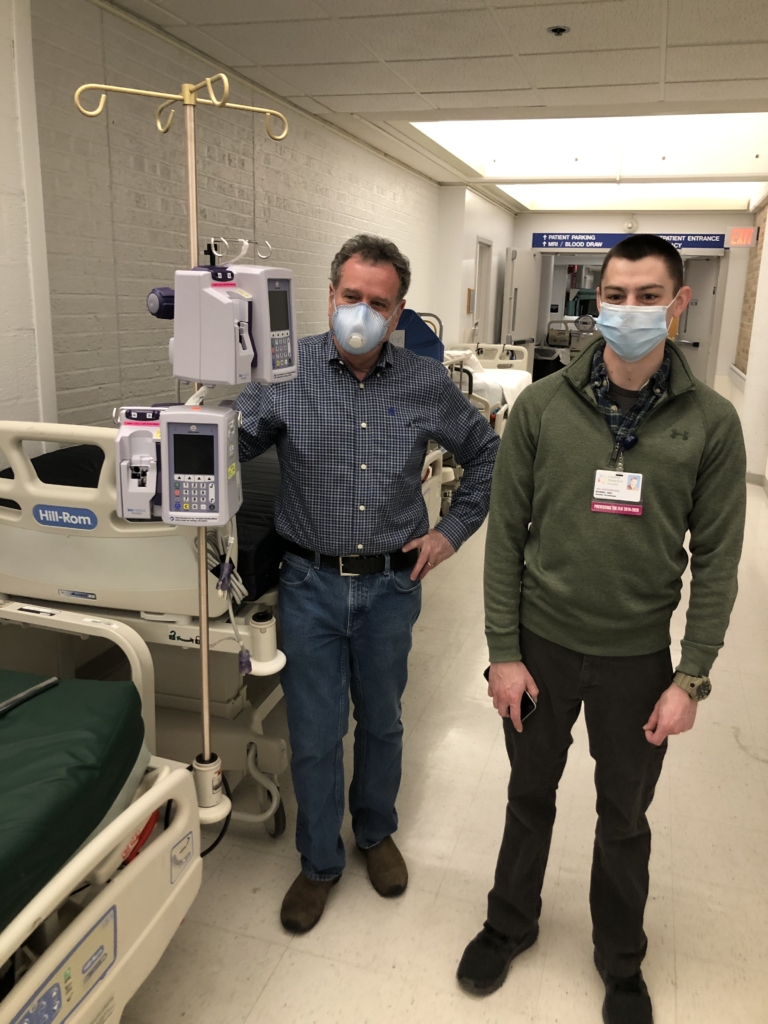

Deemed an essential manufacturer of medical equipment as defined by the Department of Homeland Security, The Bronze is a busy place these days. In addition to producing CuSalus handles (which often get installed on medical cart drawers and containers used to ship medical goods), the company recently got tapped to create antimicrobial copper IV poles. “COVID-19 patients need so many infusions that they ran out of IV poles,” Gregg explained. “We’re making 40 for one hospital and 50 for another one nearby.”

In the midst of all this, Gregg was kind enough to speak to us about the unique abilities of copper, the development of CuSalus and how it’s likely to extend beyond the realm of hospitals and factor into our homes in the near future. “I’m going to give you a lot of weedy details,” he warned us — and fully delivered on that promise. Highlights from our conversation follow.

How did Colonial Bronze get involved in the medical equipment business?

I have been on my local hospital board of directors for more than 20 years. And among the positions I’ve held on the board are I was on the Quality Committee. And among the things the Quality Committee looks at are things that cause harm. You know, hospitals are supposed to do no harm … Well, there’s a situation in this country that’s been accepted for years. And that is: You can easily catch an infectious organism in a hospital that you did not come in with. Hospital-acquired infections is a significant problem — it’s been a significant problem. But frankly, we’ve absorbed it as just being part of healthcare. To put it in perspective, you know how Dr. Fauci is saying we could lose 100,000 Americans because of COVID-19? We lose 90,000-plus every year to hospital-acquired infection … So significant human cost, significant economic cost, significant issues for healthcare.

I was looking around for something and thinking, ‘What can we come up with that will deal with these problems that the hospitals confront?’ And I was following what the Copper Development Association was doing. And at that point, they were doing some research on the antimicrobial effects of copper, because they received a grant from the Defense Advanced Research Projects Agency (DARPA) … And so they funded a multi-year study and it involved Sloan Kettering, the Medical University of South Carolina and Ralph H. Johnson VA Medical Center, because they wanted three different populations. So they installed copper alloy objects — tabletops on the bedside tables, bed rails, call buttons — anything that patients typically come in contact with. And then they followed those patients who stayed in those ICU units — whoever came in and left — over a period of three years. And when they compared them against the control set of regular rooms versus the copper-equipped rooms, patients who stayed in the copper-equipped rooms incurred infections at a rate 58% below control. When you look at numbers like that — the stuff’s not fool-proof — but when you do it on the metric of 100,000 lives, you just saved 58,000 lives.

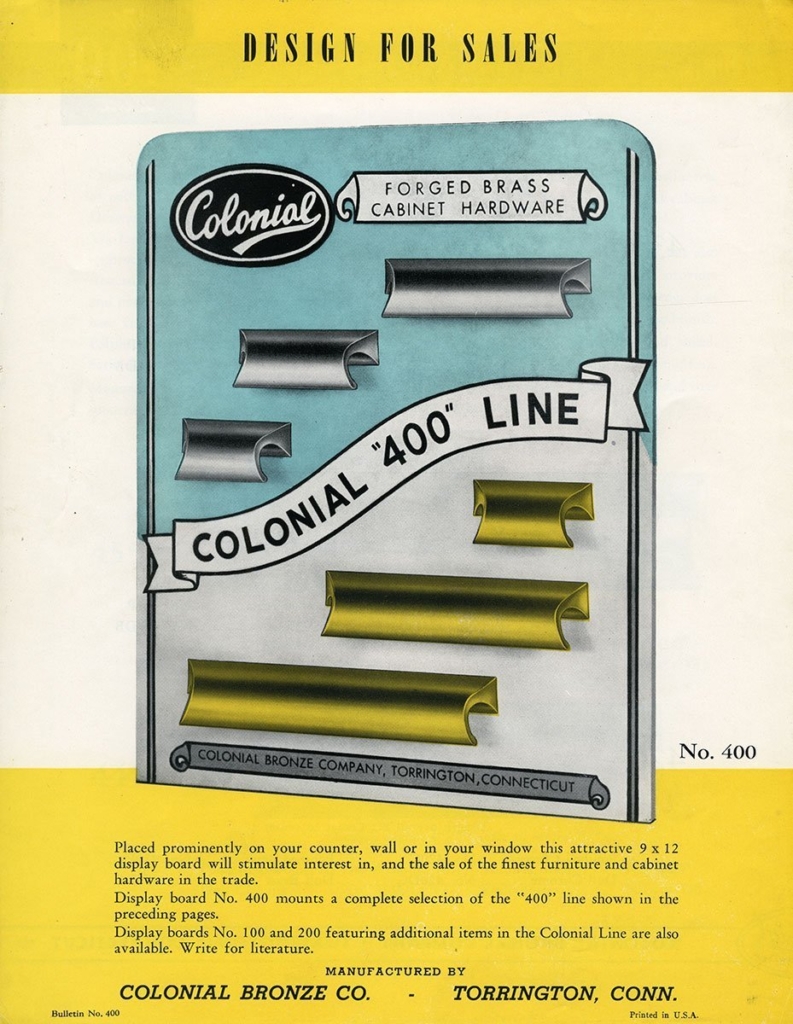

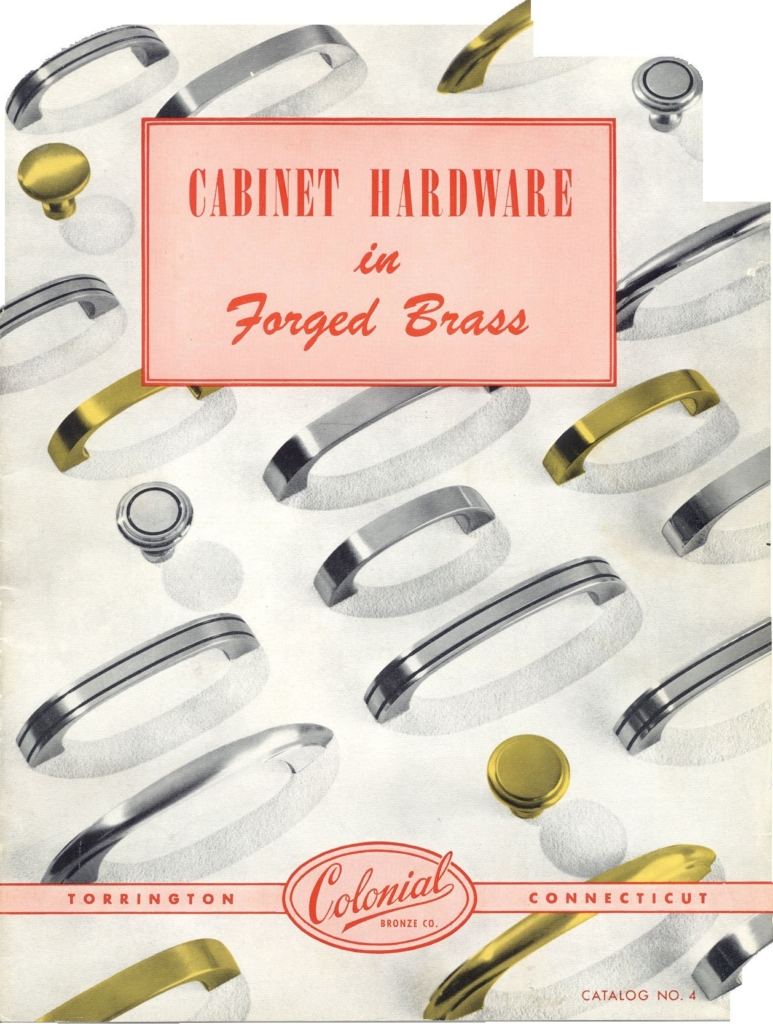

So we got involved in 2010. [Copper] is a very difficult material to machine and it’s [available] in limited formats. We gravitated into it because Colonial Bronze started out as a wire pull and mushroom-shaped knob company. [A wire pull] is just a simple handle, however it’s ubiquitous in healthcare. You walk into a doctor’s office, every damn cabinet’s got it. Every medical cart drawer has it. So when we looked at this we said, ‘You know, here’s where we can do some good.’ So we debuted the product in 2011 at the Healthcare Design Expo.

And what was the product?

It’s called CuSalus, which was me trying to be clever. “Cu” is the chemical symbol for copper and “salus” is Latin for health. So I put the two words together and CuSalus became the brand name. [In 2011], we entered that into a competition called the Nightingales. The Nightingales are given to products that represent the most significant advances [in] safety, sustainability — all things you want your product to have. And we won an award that year.

So what does CuSalus do?

I am permitted to say the following under the current regulations: In less than two hours, 99.99% of the following organisms will be dead: MRSA, E. coli, Pseudomonas, Klebsiella, Vancomycin-resistant enterococci and regular staph. Why those six bugs? Those are the ones that the Copper Development Association did their yearlong studies on … If you play by those rules and comply with the EPA’s regulations, and you meet the following three requirements: Use EPA-registered material — of which they allowed about 100 alloys of copper that had a minimum of 60% percent copper and no lead, no arsenic, no chromium. The second step is the material must be made by an EPA-registered brass mill. And third, anybody who makes anything from that material, namely us, has to be registered and listed as a pesticide device-producing facility. Colonial Bronze is listed in what’s called the FIFRA database. And so, provided you comply with those three requirements, you can say, “We kill these bugs that are hazardous to humans.”

What does CuSalus look like and how is it used in hospitals?

It looks like a standard, simple rounded handle with two 90-degree bends … When you go into a doctor’s office, those damn handles are everywhere. If you go to a medical cart manufacturer, those damn handles are everywhere. If you go to the larger diameter ones, we sell those to people who produce operating-room blanket warmers. We sell them to endoscopy-sterilization unit manufacturers. We sell the smaller, regular handles to medical cart manufacturers. Once we won that award, we thought the world was just going to beat a path to our door — and it was pretty much met by crickets. People said, “Yeah, that’s great stuff.” But they just didn’t consider it important enough. We’ve had the product line for 10 years. We sell it every year, it’s not a big deal, but we have steady customers who are always buying from us. But clearly it’s not really made for the bulk of my regular customers — it’s anything but decorative.

Is it a lot more expensive to purchase?

Is it more expensive because of the material. The two ingredients in the material we use are copper and nickel. With the current depression of our economy, copper is probably about $3.80 to $4 a pound. Nickel is about $16 a pound. Plus, it’s hard for the mills to make this stuff so they charge more for it. Its material costs are easily three times what my normal brass material costs are. But the beauty of the stuff is that, since it is the material itself that is the active ingredient that kills germs, it never goes away. It never loses its effectiveness, it doesn’t have to be replenished, it doesn’t require special cleaning … The stuff absolutely makes sense.

Has anyone incorporated CuSalus into their home?

We’ve had requests from time to time and we have sold some pieces over the years to what I usually call the Howie Mandels of the world. You know, they’re germaphobes and they want everything they can get that will reduce the viral load in their homes. Right now, this is the only material we’re using. However, I’m taking delivery of about 12,000 pounds of another alloy that we think will be more favorably received by consumers. The material comes in more shapes and sizes than these cupronickels do and it’s more easily machined. So we’re going to be coming out with a line of antimicrobial alloy hardware that is a very pale yellow. It almost looks like our brushed brass finish … We’re still conducting some tests on it in terms of cleanability and everything else, because [there’s] absolutely no coating on this stuff. You do nothing to interfere with the contact of bacteria with the surface of the metal. Because it’s the metal itself that does the killing.

So if someone has copper hardware in their home, there’s nothing they need to do to maintain its antimicrobial properties?

That’s correct. Regular wiping it down with a clean rag and maybe a little bit of soap if it gets dirty. What’s interesting is that even the tarnish that copper alloys accumulate over time … studies have shown that it actually even gets a little bit more effective because what forms on the surface of these copper alloys is something called cupric oxide. It’s basically a copper rust, just like iron oxide. And the cupric oxide kills the bugs even a little bit faster.

What’s the timeline on this new line?

Within 30 to 45 days. Because we’ve been doing this for 10 years, all of our regulatory ducks are in a row … I’ve been the point man on selling this stuff, because of my position on the hospital board. I just thought this was the greatest stuff since sliced white bread in terms of how it could help hospitals. [Now] you’re seeing people in hazmat suits walking up and down the street spraying whatever — more likely than not hypochlorite bleach or something like that — to try to kill whatever organisms are on touch surfaces. Wouldn’t it be nice to have a touch surface that cleaned itself? It gives us an incredible tool here.

Do you have a name for this new product?

I don’t yet … I’m taking suggestions from everyone. The CuSalus stuff that we normally sell is a silvery color. So I was even going down the simple road of CuSalus Silver and CuSalus Gold — just something to distinguish it simplistically and not get overly fancy or fluffy. Because what’s important is what the stuff does.

You have a background in law. How did you end up getting involved in the medical field?

I practiced law for seven years or so. And my father ran Colonial Bronze. And at one point he said, “I’m thinking about selling the place because it’s getting to be too much work for me. But before I put it on the block, I wanted to know if you had any interest in coming up to work for the family business.” And I swore I’d never do it. But then I was an assistant U.S. attorney in Manhattan and I was working seven days a week, long, long days. And it was a lot of stress. And as my father’s asking me if I wanted to come back to work for him, I’m remembering that when I was a kid, he used to come home and have lunch with my mother and go back to work. And I’m going, I’m working seven days a week, I want to raise a family, this is nuts … I want something a little more realistic that would give me a life. So I came up to Connecticut.

In my years as an attorney, among the things I did was medical malpractice defense. I would defend doctors and hospitals. And so I got a lot of exposure to medicine, to medical terminology, to having to go very deep into specific topics in which malpractice was alleged … So, when I came up to Connecticut, I got on the [hospital] board in 1996 … and I found it a very satisfying job. And that’s when I got involved in the Quality Committee of that board, looking at the issues of hospital-acquired infections … 80% of diseases are passed by touch and very few are completely airborne or aerosolized. They’re saying even COVID-19 cannot be aerosolized. It’s the droplets that people leave behind that someone else has the misfortune to touch … There was a study done in 2015 by a microbiologist who had taken a liking to this whole area and started testing alloys against a whole range of organisms. Noroviruses, HIV, H1N1, he tested it against hundreds of organisms, and he’s yet to find one that it doesn’t kill. Back in 2015, he tested the efficacy of copper as a sterilizer on a human coronavirus — not COVID-19, but another member of the same tribe called 229E. And in the context of that article, he found that it killed the coronavirus in anywhere from 30 minutes to three minutes.

Outside of CuSalus Gold, are you looking at amping up the copper content in products destined for homes?

CuSalus Gold is probably going to be able to make 70% of Colonial Bronze’s existing line. And so we will have a large variety of products.

So CuSalus Gold would be more of a material than a specific product line.

That’s correct. A material we will use to make a whole host of objects that are currently in Colonial’s regular line. The singular difference is that it’ll be unlacquered, number one. Number two, it will kill germs … I personally think it’s about time. When I was talking to the president of the hospital this past Saturday, I said to him, “I really want to get some samples of this other material into your hands … Because we know this stuff is going to work, we’ll donate some materials for the ICUs.” And he said, “I went up to our ICUs and saw your stuff that you put in back in 2013 and it still looks good. It’s still used every day. I just wished we’d listened to you … because we’d be far better prepared than we are now.” And I said, “I may ask you for a quote on that one day.”